Cross Company Inc.: An apparel and fashion corporation that develops and manages eight brands, primarily targeting women in their 20s and 30s. Founded in 1994 as a 13 square meter women’s clothing shop, they have achieved rapid growth over the past 20 years and now, this year, have achieved up to about 100 billion yen consolidated sales, with a private label apparel (SPA) business model. Now they have over 1000 shops in and out of Japan, mainly in Asian countries.

Yasuharu Ishikawa/Cross Company CEO and founder.

Born in 1970. In 1994, Ishikawa opened a 13 square meter clothing shop in Okayama City. In 1995, he established Cross Company Inc. In 1999, Cross Company changed its business model to a private label apparel model and launched its flagship brand, earth music&ecology. Cross Company is also known for achieving success in diversity management, demonstrated by the fact that the ratio of female managers reached 48%. Ishikawa also has earned many achievements in terms of his social contributions, such as planting trees in China to stop desertification.

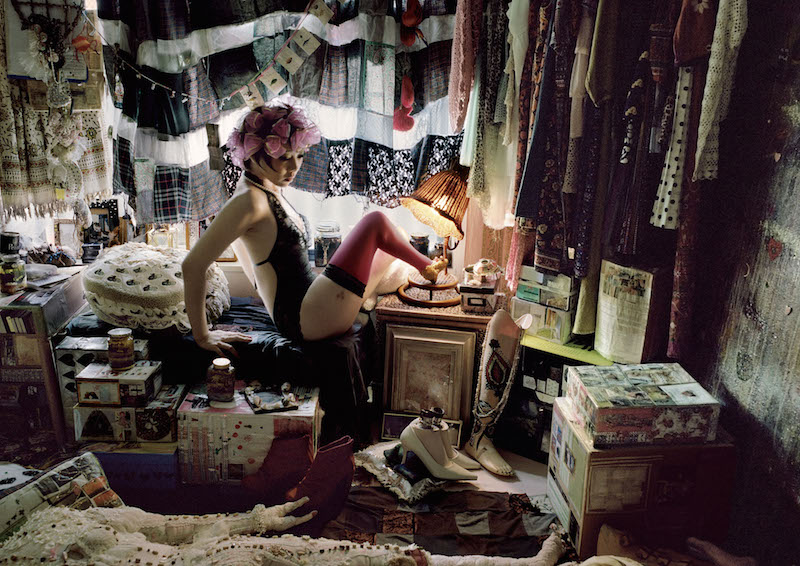

In their memorable 20th year, Cross Company has announced the launch of the new brand, KOE. KOE has caught the market’s attention for having a “fair supply chain” as the brand’s core value. This is an innovative method whereby the concept of fairness is valued and reinforced throughout the supply chain process, including ensuring safe working environments and sustainable material procurement and production. Cross Company CEO, Yasuharu Ishikawa, has underlined that they will support their world business with KOE, and that it will achieve one trillion yen in business by 2020.

We asked Ishikawa why they decided to do ethical fashion business, and why they decided to expand their footprint in the world with an ethical brand.

KOE has varieties of line-up. Not only Womenswear, KOE has Men’s and Kids’ as well to cover family needs.

— You have announced that Cross Company will expand world business with “KOE”, as a fair fashion brand. But you already have several successful brands such as “earth music&ecology,” your major flagship brand. Why did you decide to establish a new brand, instead of changing the supply chain of the currently running brands?

Currently, we have 270 shops in Japan and 500 shops in the world for “earth music&ecology.” This is a pretty big amount. If we do checks and changes with this supply chain, it surely will be a big duty. I thought it would be smoother to start a new brand with a new supply chain.

Also, we will not expand “earth music&ecology” in Western countries. We will only have it for Asian countries. And since “ethical” is an idea that is more popular in Western countries, we thought we should have that concept with the brand that we will be expanding in Western countries.

Many fast fashion companies in Europe and the U.S. are changing their supply chain to an ethical one after being criticized by consumers. However, their work is not sufficient. What we want to create is a 100% perfect ethical supply chain, and we will establish that in three years after the launch of “KOE.”

— You announced that you will aim for 100 billion yen sales by 2020 with “KOE” alone. Also, that in the near future, you will aim for a trillion yen. It seems to be a very high goal, even compared to your sales report up to this point. What does “KOE” mean to Cross Company?

We will make “KOE” our major flagship brand, aiming to make it more major than “earth music&ecology.”

The major aim for the IPO in 2016 is to raise funds for a global strategy to expand “KOE” in the world. In order to create flagship shops on major streets in major cities such as New York, London, Shanghai, and Beijing, we need to make it big—700 to 1200 square meters. That will be far bigger than the stores we have been creating for “earth music&ecology,” which are mostly about 100 square meters.

The prices will be almost equal in all shops in the world, varying from 90-110%. We even have a vision to open shops in African countries. So, in that sense, profitability in Africa will be a bit short, but we want to provide our items at the same price in any country. Most fast fashion retailers vary in price so much. We think that is not fair.

— If a company of your scale can achieve a supply chain that is “100% perfectly ethical”, I think that your brand would be the first one to achieve it. What is your plan to achieve this?

There are many ethical companies and brands that have sales of up to ¥300 million. However, for companies that are over ¥100 billion, they need strong ownership to be seriously ethical. As the founder of Cross Company, I would like to show a strong commitment and ownership myself to achieve this dream.

How are we going to set up an ethical supply chain? We are strictly inspecting our suppliers. There are 400 factories in China that we work with together for KOE. We inspected them from three aspects, including 1) human rights, 2) labor conditions, and 3) environmental conditions. We give each factory one of four grades. For example, a “Grade-A” factory is one that has no problems, but a “Grade-D” factory has serious problems in any of the three aspects, and we will stop doing business with those factories.

We inspected all the factories with our own “fair supply chain committee”. This committee is made up of employees from our merchandise and production divisions, as well as our local Chinese employees. We found that not one factory had child labor issues. However, there were 14 factories that had environmental problems that were rated “Grade-D”, and we stopped doing business with those factories.

In addition, there were some factories where the owners had an insufficient understanding of the law and made workers labor for long hours during the busy season. We have classified such factories as “Grade-C” factories and severely warned them to improve their operations.

We certify a factory as a “Grade-B” factory if there is no problem with any of the aspects. After that, an independent third-party inspection committee, which is made up of lawyers and other prominent people, will go for a surprise inspection to those “Grade-B” factories. If no problems are found, even in the surprise inspection, the factory will then be classified as a “Grade-A” factory. Our goal is to have all the factories be “Grade-A” within 3 years.

— It is well known that some factories try to hide the irregularities when inspectors come. How do you prevent that?

Indeed, it is not sufficient for a perfectly ethical supply chain to interview the factory owners alone. Actually, there were cases in which we found out some “Grade-B” factories had concealed irregularities. There are also factories that we suspect are hiding things.

So the surprise inspections by the third-party committees are conducted on a regular basis and are done multiple times. In surprise inspections by third-party committee, they do random interviews of various employees. However, we still cannot deny the possibility that the employees interviewed are acting in cahoots. Also, there are chances for “Grade-A” factories to drop their quality due to a change in owners. Therefore, we do the surprise inspection regularly.

I think that it is a distinctive feature of our company that we do double checks with our in-house “fair supply chain committee” and by the independent third-party committee.

— You say that a “fair supply chain” will differentiate “KOE” from other global fashion brands. Why do you think a “fair supply chain” can be a distinguishing characteristic?

Fashion is immediately imitated. Within a few months, everyone has the same design. However, supply chain is something difficult to build. Even if another company tried to imitate our supply chain, I believe it cannot be done so easily. That is why we think a fair supply chain will be our distinguishing value.

However, making it a strategy for differentiation is not the only reason we want to establish this supply chain. I believe “KOE”’s fair supply chain will bring a revolution to the whole apparel industry.

While still only a hypothesis, I believe that by manufacturing with a fair supply chain, the quality of our items will increase. When customers are introduced to our items, they can clearly see the difference in the quality. Customers may think, “How could this quality be possible in such a low price?” And when they find the answer—that we offer these items under the fairest supply chain—we believe that those customers would be our fans in the very long term.

As our sales expand, people will find out that true quality comes from ethical manufacturing. And as voices to demand ethical items rise in the world, I think any of the apparel companies would have no other choice than to produce things ethically.

So I believe we can change the world. The apparel industry has been ignoring this problem too long. I want to let the bells ring and say, “it’s time to change”. People are aware that the current way of production—how we have been ignoring the environment and human rights and just looking at sales—is not the way we should be developing. I will underline again that Cross Company will be the first company in the world to achieve a perfectly ethical supply chain.

— Were there any companies you studied to establish the supply chain?

It was Nestle. In particular, I studied the coffee bean supply chain, which is at the core of their long-term vision for sustainability.

With apparel, especially in the apparel industry in Japan, it is clear why people pay no attention to sustainability.

Most Japanese apparel companies only handle business in midstream or downstream of the supply chain. Upstream, the stage we procure raw materials, is mainly dependent on the trading companies. There are no people from the apparel industry who manage the distribution from upstream to midstream, and they only had the viewpoint of whether the price is cheap or whether the quality is good. None of the people managed from the viewpoint of human rights, labor, and the natural environment.

With “KOE,” we will do everything from upstream to downstream. I think that we need to research companies that are strong in upstream to midstream. That is why we studied Nestle.

The apparel industry has lagged behind other industries in creating an ethical supply chain, so there was no one we could look to within our own industry. We had to learn from other industries and enthusiastically researched them to fundamentally change.

— I heard that it was when the Rana Plaza factory building collapsed in the Bangladeshi capital, Dhaka, last year that you decided to create a brand with an ethical supply chain. However, your company has been already earning much praise in terms of its social contributions. Did you have an interest in ethical production from the very beginning?

The story is continued from when we first established the brand “earth music&ecology.” In the beginning, shirts were all made of linen, which is a material with low environmental impact. Denim items are finished in Okayama prefecture, my hometown famous for its denim industry, using environmentally friendly methods. However, as we expanded in Asia, it gradually became difficult to maintain an environmentally friendly supply chain. With “KOE,” we want to redo our manufacturing.

KOE will hold series of workshops to convey directly their value to customers. In October 2014, they held workshop to create chance to think about food with families.

— Some people criticize your company that you exploit your own staff with long work hours and extra unpaid work.

I know some people say that. However, I would like to make it clear that we are not a company that exploits our own staff. We have a culture and system that ensures no long working hours and no unpaid overtime.

We have been repeatedly telling all of our staff that extra unpaid work will be subjected to disciplinary action. In the past, when we found a staff member who did that, we demoted that person. At our headquarters the lights will be out automatically at 7:00 p.m., and lights cannot be turned on without a formal request.

I have heard of the rumor that at other companies, some people work overtime even after punching out their timecard for the day. I believe this is unlikely to happen at our company as well. We have the culture in our company that you shouldn’t be working after designated hours.

Yes, I have seen some ex-staff commenting on the internet about our bad reputation. However, at any company, employees who quit might have complaints of some kind. I believe that is not something that is unique to our company.

— Being fair and ethical are values that can’t be seen and are hard to tell consumers about. How would you like to convey the values of “KOE?”

I would like to share our vision and values through interviews such as today. Moreover, we would like to hold workshops for our customers. Also, we would like to communicate via social networking services. Actually, I would like to create movies. I think movies are a good way to tell our values; it makes it easier to understand this idea. “Ethical” is a very vague idea. I think it is very important to make it easy to understand to share our vision.